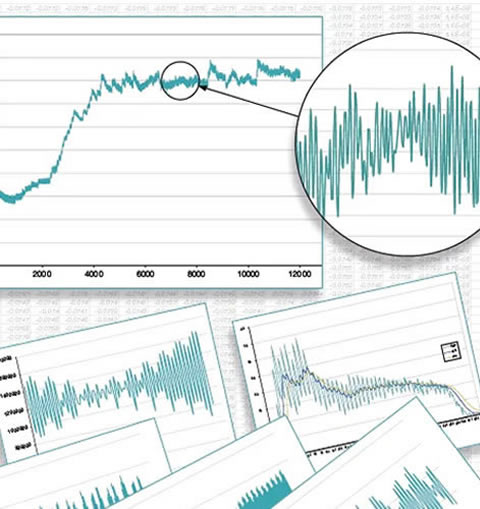

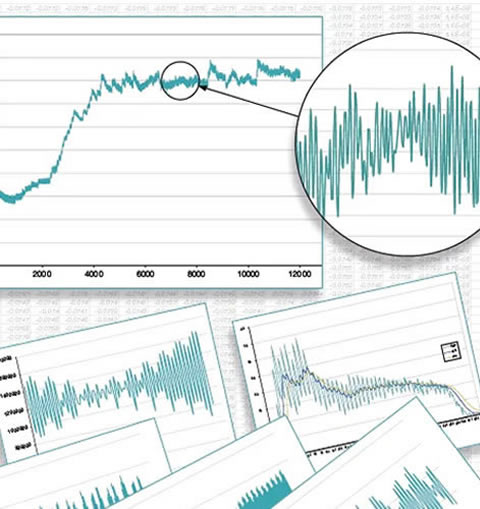

Vibration measurements are instrumental in the condition-based maintenance rotating and reciprocating machineries.

Whether it is route vibration, offline or continuous measurements health conditions can be documented, compared, and detected early before any machine outage.

Continuous monitoring systems, handheld vibration analysers, vibration meters, wireless sensors, transmitters and data loggers are brought to your from SPM Instruments, the pioneers in this technology.

Troubleshooting and root cause analysis is our specialty. We offer vibration-based machine monitoring programs, diagnostics and remote analysis as part of our engineering services.

Damping is one of the most effective methods of controlling noise and vibration. It is a process that converts vibrational energy into other kinds, eliminating the vibrational energy through friction and other processes. Increasing damping or stiffness can both reduce resonant vibration and the resulting noise by preventing the vibration from travelling through the structure.

Whether is rotating equipment, pipes or structures KEY ENGINEERING can offer the right solution to beat resonance phenomena.

Datum Hawk is an advanced self-learning condition monitoring system, capable of analysing each individual cylinder of the engine from the dynamic torque signature. Coupled with the Datum Shaft Power Meter, Datum Hawk represents the ultimate sensor system for real-time condition-based ship monitoring, allowing for sharply-focused preventative maintenance, thereby providing savings of both time and money.

Datum Hawk is a “Smart”, intelligent system, capable of carrying out the torsional signature analysis of main engine(s), auxiliary engine(s) and diesel generator(s). Giving a true insight to the vessel’s mechanical health.

KEY ENGINEERING supplies tailored made continuous monitoring system for various process signals. Our attractive price to performance ratio makes it possible for the first time to equip many machines without sacrificing cost- effectiveness and quality.

With high-capacity system, other process parameters besides vibration data, such as temperature, load, and speed, can also be recorded.

Let the Service team of KEY ENGINEERING do the tele-diagnostic service, which provides broad information basis makes it possible to make comprehensive statements about the machine condition that are not possible with “isolated” monitoring systems.

Integration to your control system such as SCADA, BMS, or DCS is possible. Innovative cloud monitoring solutions, with real time monitoring, data analytics, machine learning for different applicatrions are within our expertise

The lubrication system ASSALUB corresponds to the current level of technology and the recognized rules of safety practice.

It dispenses the right amount of lubricant at the recommended time interval which gives better control on lubrication in comparison to the manual lubrication. Thus the friction moment in the bearings is minimized and less or over lubrication conditions are avoided.

An essential factor for the performance capability and the rating life of a rolling bearing or a linear unit is the correct selection of a suitable grease. With the competence available, the rolling bearing or linear system as a machine element can be given advantages in terms of reliability and rating life on the way to realising an application. For decades, there have been researches in the development and application of greases in order to determine which grease provides the best solution for each application. Greases have for decades been a guarantee of the highest performance capability in rolling bearing and linear applications. All greases have been subjected to a demanding test of suitability.

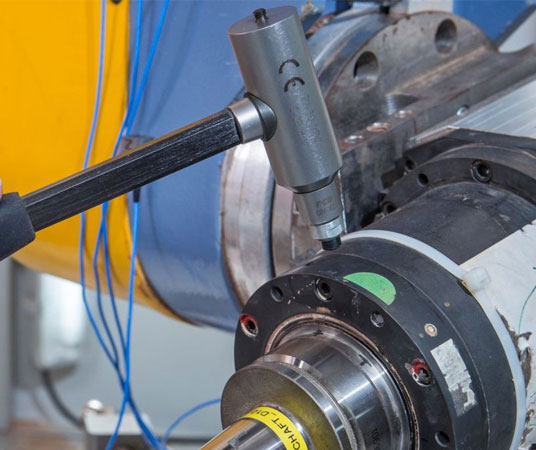

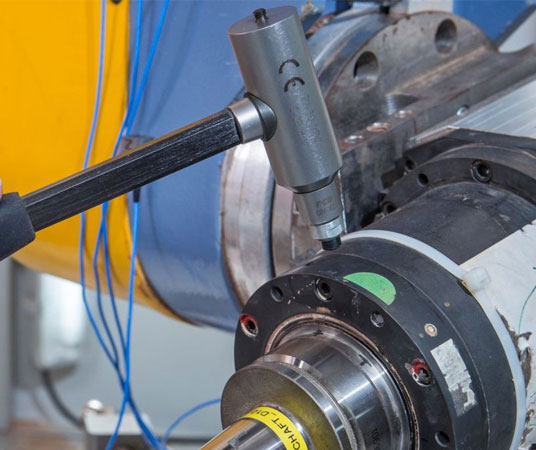

Unbalance is one of the big four malfunctions in rotary applications and the most frequent culprit of increased vibrations in fans, ventilators, belt pulleys or couplings. The objective of field balancing is to keep vibrations, mechanical stress, bearing loads and shaft deformation within acceptable levels.

Our service experts can use different balancers to quickly identify and eliminate unbalances in the field, under challengeable operating conditions. Maintaining residual unbalance that is complaint with the residual vibration according to ISO standards or balancing quality grades.

Reduce costs by reducing power consumption, reducing machine vibrations, increasing the bearing and seals lifetime.

Best performers who care about Maintenance Reliability employ precision maintenance practices with super accurate, reliable and user-friendly alignment systems, which measure and align machinery used in the power, chemical, water treatment, production and processing industries.

Let the Service team of KEY ENGINEERING with its dedicated experts and systems be at the heart of your maintenance program.

No matter the machine arrangement, our team masters alignment of horizontal and vertical mounted machines, machine train, or with cardan shaft, spacers, bore alignment, straightness and leveling.

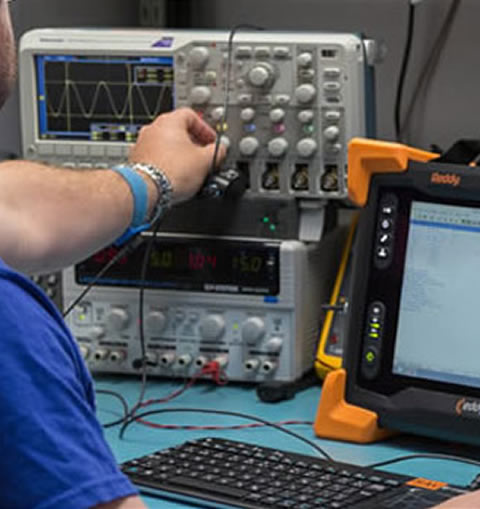

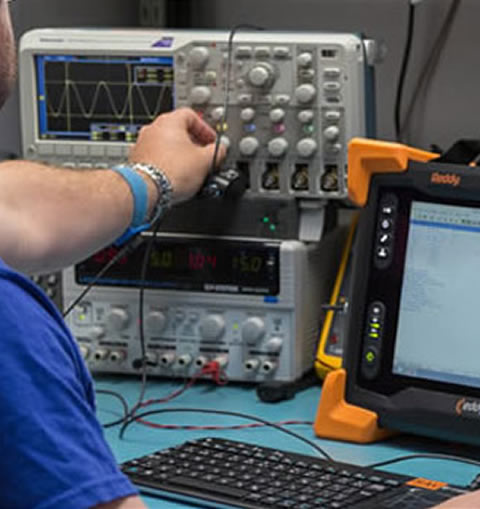

KEY ENGINEERING offers wide range of calibration services for test, measurement and process instruments. With master instruments calibrators we can meet the requirements of UCAS, ILAC and other known accreditation bodies.

Whether it is Temperature related instruments, Electrical, Electronic, Humidity, Sound and Vibration or other process instruments, calibration management service can be optimized with documented procedures and calibration results, plus reports that all comply with quality standards like ISO 9000, ANSI Z540 and ISO/IEC 17025.

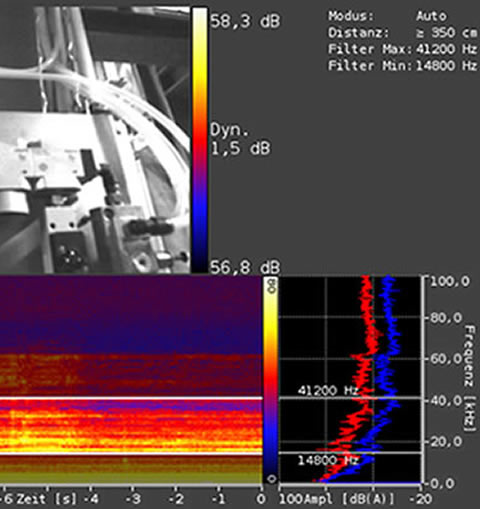

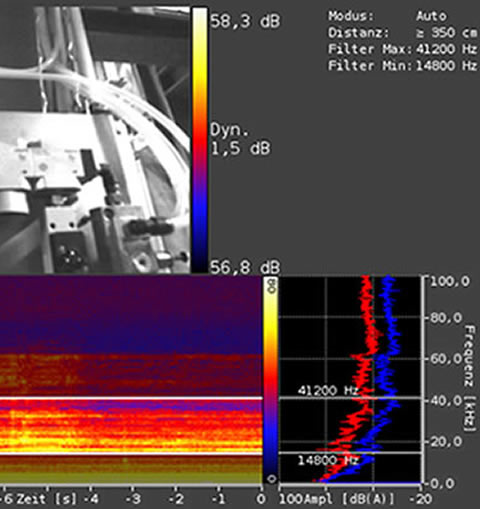

The state of art technologies of ultrasound are embedded in the products of SDT, the digital instruments can help the maintenance personnel to evaluating a bearing running condition, lubrication condition and many others such as:

Selection of the appropriate method and tools for bearing dismounting and dismounting is paramount to prevent the bearing, bearing seat and shaft from damages. KEY ENGINEERING offers wide range of thermal and hydraulic tools for the safe and mounting of the bearings.

Mounting is one of the critical stages of the bearing’s lifecycle. If the bearing is not mounted properly using the correct method and tools, the bearing’s service lifetime will be reduced. Around 16% of all premature bearing failures are a result of poor fitting or using incorrect mounting.

It is extremely important to dismount it correctly so that the service life of the replacement bearing is not compromised.

Firstly, the use of proper dismounting methods tools will help prevent damage to other machine components, such as the shaft and housing, which are often reused.

Secondly, incorrect dismounting techniques can be hazardous to the operator techniques. If you need a support in mounting or dismounting medium and large size bearings, KEY ENGINEERING can be at your service.

The quality services of maintenance, repair and operational services for MV and LV electric drives that are accompanied with competitive price rates, fastest delivery times assure minimum outage of your rotating equipment.

Our rewinding and overhauling works comply with international standards and best practices of our partners.

Emergency service calls for an unplanned shutdown of your critical assets us always possible at KEY ENGINEERING as we have the capabilities to work around the clock

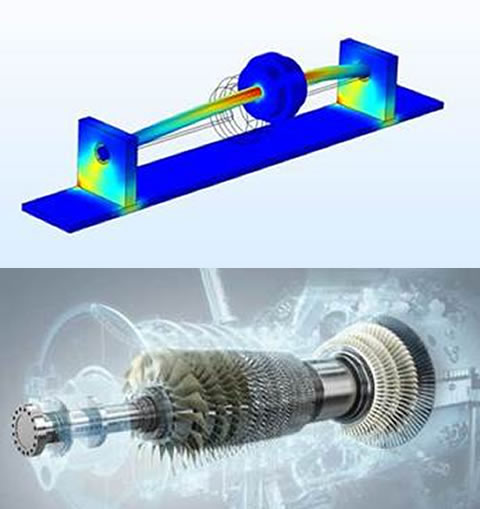

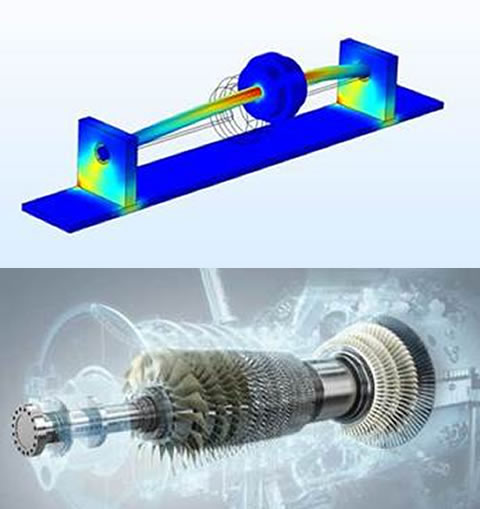

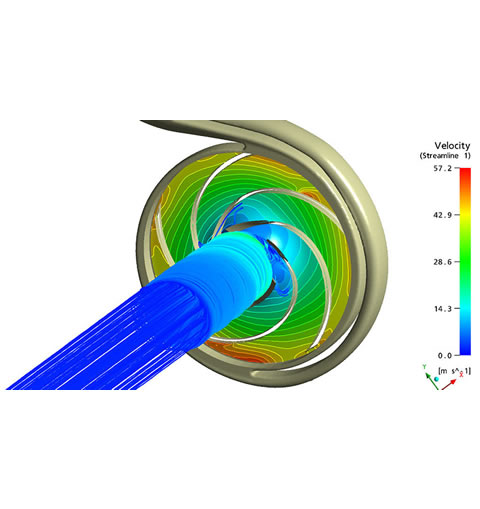

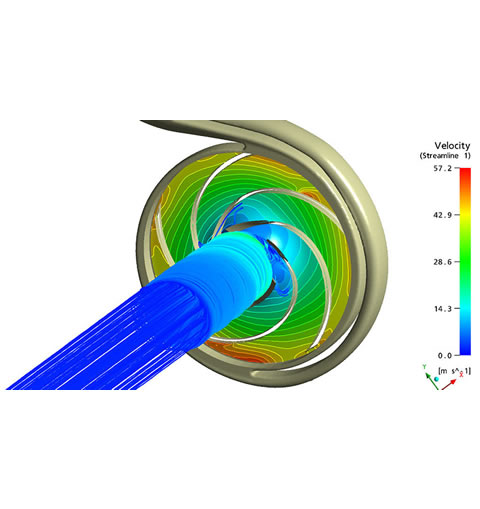

Static and dynamic analysis of rotors and rotating machines is paramount to avoid unnecessary vibration and ensure the reliability of the machines. How does your shaft move in the hydro bearing during startup, shut down and under the loads from an operating cycle?

An efficient measurement and analysis technique can provide insight into the source of the unbalance, origin of static, dynamic loads and avoid vibration issues.

Rotor dynamics measurement techniques involve analyzing the operation of the machine at various speeds and operating loads using probes and keyphasors. A smart combination of several analysis plots, such as orbit, centerline, polar, full-spectrum plot, and operational deflection shape provides a detailed analysis of the rotor unbalance, shaft motion, and the structural behavior of the complete installation. In this webinar you will learn about:

Experimental Modal Analysis is an effective instrument for extracting the modal parameters, and understanding and modelling the dynamic behaviour of assets and structures.

It can be carried out both to determine the natural frequencies, damping and mode shape to verify the design, optimize and validate a finite element model (FE) or extended to troubleshoot a vibration problem.

Thanks to ME’scope where EMA can be carried out for the best analysis of both data acquisition and the subsequent parameter identifications. It has been widely utilized for broad applications in automotive, civil engineering, power generation and industrial sectors of heavy industries.

Prediction of asset performance requires accurate mechanical machine model-based monitoring, application of gas thermodynamic and fluid dynamics theories and adequate calculation tools.

Today, predictive techniques commonly implemented are connected to the reading of vibrational parameters and, in general, to machine mechanical indicators (mainly bearing vibrations and temperatures), where the observation of vibrations and temperatures provides a way to avoid dangerous operative conditions, triggering alarms and trips.

The starting point of the method is the availability of reliable reference performance curves along with relevant gas mix composition and thermodynamic conditions (pressure and temperature). With this input data available, it is possible to predict the performance and efficiency of the machine which benefits the maintenance planning and production professionals in planning the turnarounds.

Copyright © 2024 www.ketgulf.com

All rights reserved.

Copyright © 2024 www.ketgulf.com

All rights reserved.

Social Network